General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What is Black Printed Circuit Board

Simon / 2021-05-30

Contents [hide]

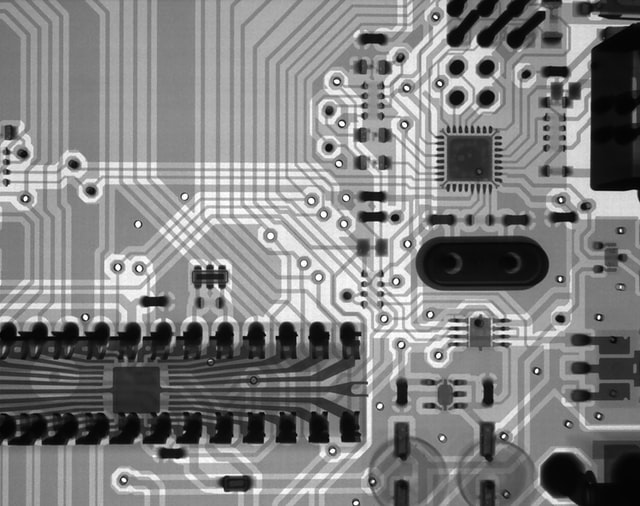

Printed circuit boards are used to mechanically support electrical components into a workable electrical circuit. These electrical circuits are then used in manufacturing electrical machines and gadgets like computers, TVs, and communication devices. A printed circuit board comprises one or more copper sheets separated by a substrate, and obviously the electrical components such as resistors and capacitors.

The board, from appearance, can be of different colors, mostly green but also black. The solder mask is what gives the board its color property, it can be black, red, yellow, matte, pink, purple, or of mixed colors. Hence black PCB boards or printed circuit boards have black solder masks.

What is a Black Printed Circuit Board?

As the name suggests, the black printed circuit board is a black-colored circuit board whose solder mask is black. This mask coating is necessarily the only black material on PCB board, although other materials can also be black. The solder mask is a thin layer covering the copper traces in the board, but its use is not just to make the board black, it determines the performance of the board as well.

Types of PCB Colors

The most common color on PCB boards is green. However, you will also find other colors such as black, blue, and yellow. Therefore, the color is on the coating. The significance of this coating is to protect the PCB board. For instance, the coat protects it from wear and tear when exposed to high humidity, temperature, and other factors. It also secures the material on the board. The other function of a colored coating on the board is to give it some visual appeal. Some manufacturers and designers like using other colors to break from the monotony of the green. Most companies are also trying to come up with a color based on their understanding of what their customers like.

For that reason, you find:

Blue circuit board - This is the second most popular after the green circuit board. The blue color makes the board easy to repair and assemble because of the high contrast between the color and that of copper wires.

Red circuit boards - Red color is for the bold. Red also produces high contrast between the planes, traces, and spaces on the board. Hence, it becomes easy to spot any damages on the red board, which makes the boards easy and quick to repair. The color also works well with magnification when using magnification to identify traces on the board.

Black circuit boards - It is one of the most complicated types of PCB board. Black PCB boards have hard-to-identify spaces, planes, and traces. For this reason, they are hard to repair. It is also not easy to inspect the board or identify traces or imperfections on the board without special illumination. The board also must be tilted across the light beam to ease inspection. Spots can easily be marked and identified using a different silkscreen on this type of board. The black PCB boards, however, despite being hard to manufacture and design are the hardest to copy.

White circuit boards - This would be the worst choice of color for the circuit board as there wouldn't be any contrast at all for spaces, planes, and traces. Whiteboards are therefore harder to work with than black PCB boards because the contrast wouldn't be easily visible even over a beam of light.

Purple PCB boards - Purple color is not common for PCB boards and may come with additional costs.

- Other colors to use on boards are yellow, which offers great detail of contrast between empty spaces, traces, and planes on the board; green, which is commonly used because green visuals help reduce fatigue, renders the best contrast properties for the spaces, traces, and planes on PCB boards, and is widely used as color code for PCBs and therefore makes it possible to print PCBs in masses.

Black PCB Materials

Black printed circuit boards are made of different materials. The PCB black solder mask is used instead of masks of other colors. This mask is made of resin materials. The use of resin renders the material high humidity resistant and offers very good insulation properties. Another advantage of using resin is that it is resistant to solder. The resin also renders the board high resistant to temperature, meaning it can stay in heated places for long without damage.

The board is cleaned and freed from rust first before this resin is applied. Cleaning also ensures the removal of oxidation on the board. After cleaning, the board is placed on a black film and then resin released onto it. Manufacturers use a syringe or plunger to release the resin on the board. The amount of resin to be used depends on the size of the board. Manufacturers determine the amount of resin to be applied first to avoid using too much or too little.

A transparent black film is laid over the resin on the board to spread it evenly. This ensures the resin can spread on the board without leaving out any spots. A piece of glass is also laid on the film to assist in ensuring the resin spreads out well.

Another material, a squeegee, can be used to help distribute the resin on the board. This allows the resin to reach the corners. However, applying too much pressure on the board produces bad spots. This affects the functioning of the board. Air bubbles may also form during the squeegee process, and this affects the functioning of the board. Therefore, the process is done slowly.

A solder mask is placed on the PCB after spreading the resin. Film alignment is then done. Alcohol can also be added to the back of the mask to bind it to the clear film. The board is then exposed to UV light for about 10 minutes. The distance of the source should be 2-3 inches away from the board. The film is then peeled off the board.

The coat is applied on the board manually or automatically. Different types of coats can be applied on the black PCB including acrylic, urethane, silicone, and varnish. The acrylic coat provides good elasticity and protection to the PCB. They are also easy to apply and rework. The manufacturer or designer can remove them quickly and easily when the need arises. If boards are likely to be exposed to chemical, moisture, and mechanical damage, urethane is a more desirable type of coating for a black PCB.

Otherwise, the Silicone coating is an excellent type when the board is exposed to high temperatures. It offers excellent chemical resistance. Varnish coats also provide high insulation and stability properties. Hence the type of coat material to be used depends on the application, desired performance, and desired properties of the board.

Benefits of Using Black PCBs

Below are the advantages of using the black printed circuit boards.

Low reflection of light - Since black is a poor reflector and good absorber of light, black circuit board materials are used in circuits where light reflection is not needed. This is for instance when glare is not needed and where board inspection uses the light method.

Highly versatile - The boards can be covered with coatings of different properties including chemical, mechanical, and moisture resistance properties.

Are visually appealing - Black is visually appealing especially when on the board that holds shiny metal components in the circuitry. Some people also associate black with luxury. Black is used by many big brands such as Apple to connect people to their properties.

Promotes anti-plagiarism - Black PCBs feature copper traces that are difficult to figure out when looking at them with a naked eye. They are therefore difficult to pirate by simply following the design traces. It is more difficult to punch holes on a black printed circuit board. The board is also hard to plagiarize given the high costs of production when compared to other types of boards.

Limitations of Black PCBs

Hard to manufacture - The black PCBs would need a decent source of light to illuminate when tracing the paths. Manufacturers and designers find it hard to work on the board because the routing paths are not easy to follow when designing and manufacturing the board.

Less resistant to scratching and bumping - This board can pick blemishes easily in the form of small scratches and bumps. This may happen during storage or transportation. Blemishes will make the board old and less attractive.

Black ink is slightly toxic and more expensive - The black inks are more expensive than green inks. In addition, the chemicals in them are more toxic than those in the green inks. Black ink gives more trouble to wastewater treatment factories than other inks when disposed of.

Conclusion

Black PCB boards are an excellent choice for luxury and visually appealing boards. They are used to mask the circuits and make them harder to plagiarize. This is because it is not easy to identify the planes, spaces, and traces on the boards. Also, the board is pricy to manufacture in masses, which discourages illegal reproduction. However, this board makes products hard to repair and maintain.

Previous article:What is A PCB Mount Transformer