-

Capacitor

-

Resistor

-

Diode

-

Triode

-

Fuse

-

BGA

-

QFN

-

QFP

-

PLCC

-

SOP

-

DIP

-

transformer

-

relay

-

switch

-

connector

Competitive Price

- Starting price 100USD

- No stencil price

- No fixture price

Passive Parts Free

- Use our inventory turnkey orders of passive components

- Passive components shall be free

Quick-turn

- Online instant quote

- 8H and 24H urgent ship service

Superior Quality

- Auto Solder-Paste Printer with SPI

- YMAHA & Panasonic Surface Mounter

PCB Assembly

Profession,Quality,Responsibility

Online Quote over 95% accurate

8H Expedited Delivery

Turnkey BOM Sourcing

10PCS Assembly starts at $100

-

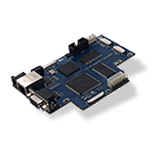

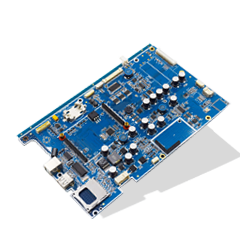

Rigid PCB Assembly

-

Flex PCB Assembly

-

Rigid Flex PCB Assembly

-

Box Build Assembly

Quality System

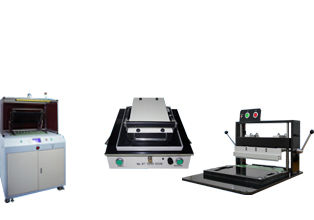

Adavanced Quality Inspcetion Equipment

- IPC-A-610FStandards

- ISO9001Quality System

- Over 99.5%Qualified Rate

- Under 0.2% Complaint Rate

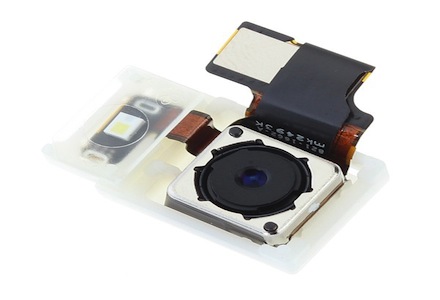

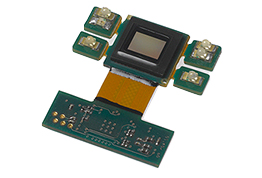

X-Ray Inspection System will inspect your area array packages such as CGAs,BGAs and CSPs to ensure the assembly meets the highest quality levels.

-

Automated Optical Inspection (AOI) systems with IPC610-D standards for every components avoids the soldering defects

-

Oven thermal profiler help define, measure, monitor, and improve thermal processes for improving our soldering quality

-

Functional Circuit Testing(FCT) is a quality assurance (QA) process and a type of black-box testing that is the best way to check whether the PCBA is working properly

-

.jpg)

Oscilloscope,Bridge,Microscope and other testing instruments are used by technicians to ensure quality in the detail execution from parts IQC to PCBA OQC.

Testing Procedures

Various testing method will be applied

to the assembled boards before the

final shipment

Visual inspection

X-ray Inspection

AOI Testing

ICT

Functional test

Our Printed Circuit Board Assembly Capabilities

Assembly Types

- Surface Mount (SMT)

- Thru-hole

- Mixed Technology

- Single or double sided placement

Turn Times

- Normal:3-5 Days

- Express:8-48 Hours

Volume

- No minimum order quantity

- Engineerring prototyoes

- Mass manufacture

Parts Procurement

- Turnkey

- Kitted/Consigned

- Partial Turnkey

Stencils

- Laser cut stainless steel

- Assembly order for free

Component Types

- As small as 0201 & 01005 package

- As small as .4mm pitch

- As small as 12 mil pitch

SMT PCB Type

- Rigid-Flex

- TFlex(PI, PET)

- Rigid (FR-4, MC, Rogers, etc.)

SMT PCB dimensions

- Smallest:5mm*5mm

- Largest:1200*400mm

Testing Produres

- Visual Inspection

- AOI / ICT

- X-ray Inspection

- Functional Circuit Testing

Solder Types

- Lead-free / RoHS compliant

- Leaded

- No-clean process available

Our PCB Assembly Requirements

- No. File Format BOM Items Centroid File Items Component Package

- 1 PCB(.pcb, .pcbdoc, .brd, .cam,Gerber) Reference designator X / Y - Centroid location (mils / in) Loose parts and bulk

- 2 Centroid file(.xls .csv .xlsx .txt) Description Layer / Board side / (top / bottom ) Tube and tray

- 3 Assembly Drawings(.pdf) QTY Rotation / theta Reels

- 4 BOM(.xls .csv .xlsx) Mfg P/N # Reference designator Cut tape