General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

How to Desolder PCB Capacitors

Simon / 2020-11-21

Contents [hide]

A Printed Circuit Board (PCB) comprises electrical components like diodes, transistors, fuses, resistors, and capacitors. Each component has to perform efficiently for the PCB to function. A capacitor is very much like a battery but with a different task to perform. A battery uses some chemicals to store electric energy and later release it through circuits; it can take up some time-even years. On the other hand, a capacitor releases its energy rapidly in seconds or less.

Capacitors come in different shapes and sizes but usually have two conductors commonly known as plates. In between the plates is an insulator called a dielectric. The plates are then wired to electrical connections on the outside, referred to as terminals, each on its own.

In PCBs, the dielectric can block the direct current flow, but the indirect current keeps flowing. When the capacitor stores energy, the current keeps flowing, but when full, the current stops. These capacitors can go bad and are replaceable by desoldering. This process of desoldering is what we're going to talk about today (If you still want some brand new PCBs, talk to us for more details.).

Why Do You Need to Desolder?

A capacitor's job is to allow the free flow of AC. One that performs efficiently will hold its charge and look just okay. A failing one tends to leak electrolyte, which forms a brown, orange, black, or even white discharge on the PCB. The capacitor also tends to bulge at the top part where vents are located, which makes the capacitor unable to release the hydrogen gas that builds up in them. The capacitor then pushes the gases and the electrolyte out on the PCB.

The PCB is usually upright, and the leaked electrolyte can make a trail down the board. The electrolyte is a corrosive element and can damage other components of your PCB.

In cases where the capacitor is hugely damaged, it can tend to blow apart and leave a roll of dielectric material on the PCB. A damaged capacitor is one reason you may need to replace the capacitor by desoldering the damaged one and replacing it with a good one.

You may also need a component- the capacitor in this case. If you do not want to buy some, you can get some from old analog PCBs by desoldering them straight off those boards.

Let's now explore the two common ways of desoldering PCB capacitors along with a few tips and tricks you can employ to achieve a perfect job.

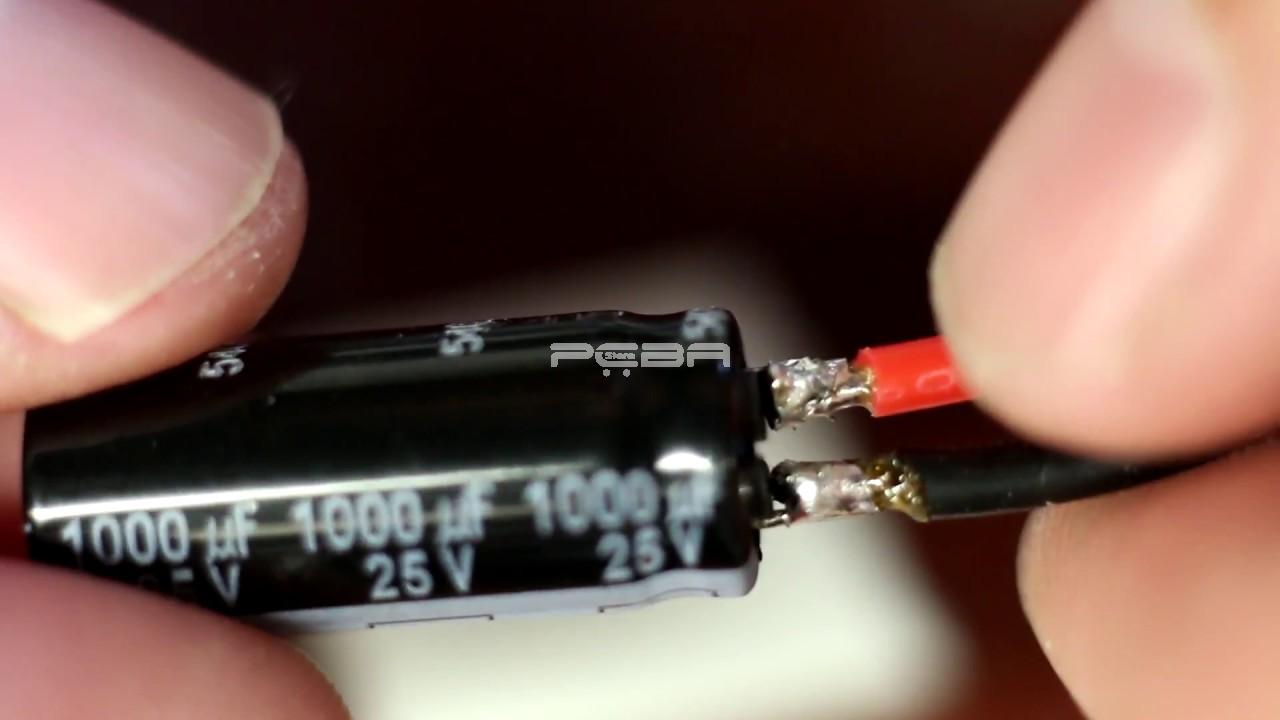

Steps for Surface Mount (SMD) Capacitor Desoldering

You'll need a soldering iron with an adjustable temperature range. Turn the iron on and set the temperature to 370 degrees. Mount the PCB on the circuit board holder, with the components to be desoldered facing up. Ensure both the board and the holder are free of moisture.

Firmly hold the capacitor to be disordered by the middle with a pair of tweezers. With the soldering iron, and still holding the capacitor with the tweezers, touch one of the soldered terminals with a hot soldering iron tip. Maintain this contact for two to three seconds, then shift to the other terminal. Touch again for two to three seconds and repeat the cycle for as long as it takes to soften the solder.

Once ready (soft), try to wiggle the capacitor. If it is indeed loose, pull it out the capacitor using the tweezers. You'll need to clear the flux. To do this:

Place a copper braid on top of the pad from where you removed the capacitor.

Maintain a gentle press on the braid using the tip of the soldering iron.

Keep the contact till all the flux is absorbed by the copper braid.

Do the same for the other pad.

Finish off by cleaning the pads in a piece of cloth dipped in alcohol.

Step for Regular PCB Capacitor Desoldering

Plug in the soldering iron and set the temperature to 370 degrees. Just like with SMD desoldering, mount the PCB on the holder. Identify the components to be desoldered and have them facing down on the circuit board holder.

You need to get the solder flux absorbed and not just melted. To achieve this, place the copper braid at the point where the capacitor lead and the corresponding pad meet press the soldering iron tip against the copper braid until all the solder flux is absorbed. Repeat this step for the other lead (capacitor pin).

Unmount the PCB and mount it with the components' side facing up. With a pair of tweezers, lift off the capacitor. If it doesn't come off the board, touch the junction of the capacitor leads and the pad. This should liquefy any remaining solder flux, releasing the capacitor. Clean both sides of the PCB with a piece of cloth dipped in ethanol, or simply alcohol swabs if you have them.

Tips and Tricks for Desoldering PCB Capacitors Like A Pro

1. Determine What Type of Soldering Iron to Use

There are many cheap soldering irons available in the market, but if you are a newbie, then it is better to talk to a professional.

When looking for a soldering iron, you need to consider a few aspects. There is already a sizeable number of these soldering in the market that heats in less than a minute. Still, want to be faster? There are still affordable brands that are ready in 30 seconds of heating up.

There are still advanced models that feature temperature control. These are the soldering irons you need for the sensitive components. You can still turn up the temperature for a bigger component- quite fantastic! The off/on function is also available in most modern models. This ensures the strip's lifespan is not shortened, should you forget to unplug it.

One other thing to look at is the cable. Ensure you go for one with a flexible cable that's not problematic to use in tight corners.

2. Buy the Right Circuit Board Holder

A circuit board holder simplifies your work of extracting those active and passive electronic components. You might be wondering what these components that I just mentioned are, but relax. Active electronic components require power to function. Such components include chips. On the other hand, passive components do not need external power to function. These components include resistors and capacitors.

A circuit board may be bought or made at home. Should you choose to buy one ensure, it has all of the essential features. These may include attachments for placing other tools, such as a brass wire for cleaning the soldering iron tip.

A homemade circuit board holder works as fine as a purchased one, except that the former's efficiency entirely depends on your creativity, innovativeness, and craftsmanship. Nevertheless, if your holder has the jaws or mechanism for clamping the boards, you may forego other features such as a solder spool dispenser and a brass wire holder.

3. More Solder to Desolder!

When trying to heat the contacts to melt the solder, it may fail to melt! Quite unfortunate for you, but fortunately, I have found a way around thin. You need to add a little more solder and watch the magic. This trick is incredibly helpful when desoldering components with many leads. This is so because the more the solder, the longer the solder glob remains liquid, giving you ample time to pry out the component.

4. A Blowtorch Could Be Better

You can also use a blow torch instead of the soldering iron. This would be particularly helpful when you have huge capacitors to desolder. This trick shortens a job that would typically take a minute or two to less than 10 seconds. You need to understand a few things regarding this shortcut- as you know, shortcuts are never the safest.

You must not burn the PCB. Burning circuit boards produces carcinogenic fumes. Avoid burning the board as much as you can. To use the blow torch effectively, ensure the flame is as close to the solder joint as possible.

If you do not have a blow torch but still have a massive desoldering job, you can first heat the PCB with a hairdryer. This raises the temperature so that less heat is drawn from the desoldering points. The few seconds you save per joint might amount to a significant period.

5. How About A Rotary Tool?

Ever tried desoldering big transistors or ICs with thick leads? Guess you gave up after damaging every lead that you tried desoldering capacitors. This is precisely where a rotary tool should come in. A rotary tool saves the precious component from ruined leads, as well as your wire cutter's cutting edges. This is a shortcut too. It would be best if you thus were very careful not to cut into the PCB. Avoid cutting into the solder joint to avoid creating toxic lead dust.

6. Breaking Can Be Acceptable

Suppose you wanted to desolder a heatsink? You may not have given it a thought but come to view it this way- heatsinks are meant to 'sink' away from the heat. Heating a sink with a soldering iron tip will be no different from trying to suck a river dry from a small pump. It's your fuel that will deplete. So, how do you remove a heatsink from a PCB? You only have to break it! You need to do it carefully not to hurt your palms, and in a well-ventilated area to minimize inhaling PCB dust.

7. Dusty Hands Are Better

And lastly, this is heat we're dealing with. You sometimes touch the tip of the soldering iron by mistake. To reduce exposure time to the hot element, keep your hands dusty. Apart from the dust layer being an insulation layer somewhat, it also makes the soldering iron slide off your hands before you get seriously burnt.

Conclusion

Desoldering PCB capacitors has never been easier. The steps and tips outlined in this guide should help you desolder those PCB capacitors without damaging them or the board from which you'd be desoldering. Thanks to the tips also, you can do the whole process safely and effectively.