General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What is PCB Panelization

Simon / 2021-08-14

Contents [hide]

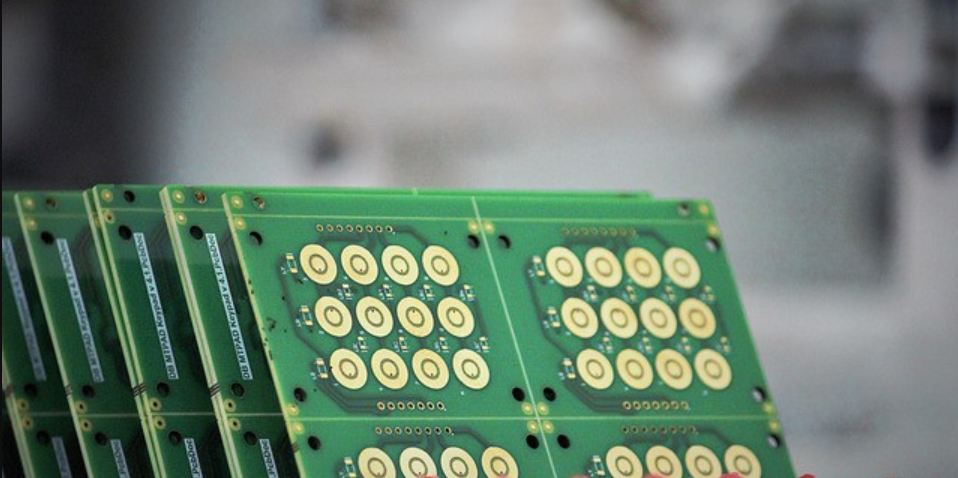

The process of PCB panelization is an important step in the PCB design process. Panelizing a PCB allows it to be broken up into smaller pieces to be more easily manufactured and uses materials more efficiently. There are many advantages to this approach, including lower costs for manufacturing. It also breaks up the larger board into smaller tasks that can keep production time shorter than if only one large board was produced all at once. This article will discuss everything you need to know about PCB panelization, including how it works and how it can benefit your designs today.

What is PCB Panelization?

Panelization is the process of breaking a PCB design up into smaller pieces so that, for example, it can be manufactured more easily and efficiently. The PCB panelizing tool then creates these panels to produce a complete circuit board. To enjoy the benefits of everything about PCB Panelization, it's critical to factor some design considerations as follows;

PCB-array strength

Additional measures need to be taken to provide the desired electrical characteristics, such as a thicker copper layer and larger trace width.

For circuit patterns with a small pitch, it may become difficult to maintain good dispersion when shrinking the pattern size too much for manufacturing.

Component layout

This refers to the components or "Components" layout on the board. You must consider how they will fit into a panel and if you need any modifications to ensure that they can be mounted easily in manufacturing.

Assembly

You should also take into consideration how the panels will ultimately be assembled to create the final product. You must make it easy for the manufacturer to assemble them into a complete circuit board.

PCB shape

The PCB must be trimmed to fit into the panel or panels. The edges of these panels can then be mitered, which makes it easier to assemble into a completed board. There are two common ways to create an edge: V-groove and tab-routed. Each has its benefits when creating a PCB that is easy to manufacture.

Tooling holes

Many holes will be drilled into the board at some point in the manufacturing process, such as mounting holes and feature drilling. Since these can affect assembly time, it is important to consider where they should go and any modifications to their position on each panel.

Advantages of PCB Panelization

1. Saves you time and money

The PCB panelization tool can save you time and money by breaking up the larger board into smaller tasks, keeping production time shorter.

A PCB in a box is expensive because it takes so much material to produce one large circuit board; PCB panelizing allows for more efficient use of materials, resulting in lower costs.

The PCB panelizing process also speeds up manufacturing since fewer boards are produced at once than when they're all done together on a single sheet. This means you won't have long periods when your work isn't completed, or products aren't shipped out. If you're making small batches periodically (rather than all at once), then multiple projects may be happening simultaneously, which means that they're all progressing at the same time.

Finally, PCB panelization may make design changes easier since you're not trying to change a single large board but instead smaller boards that are much more manageable.

2. Improves Work Efficiency

Because PCB panelizing breaks the circuit board into smaller pieces, it allows for more efficient use of materials. This means that you'll save money on manufacturing costs and will be able to complete work faster than if one large PCB was being produced all at once.

It also speeds up production time by not having long periods where your work isn't getting completed, or products aren't being shipped out since PCB panelization divides things into small batches rather than waiting until everything is done at once. Pcb panelization also allows for design changes to be made more easily since you're not constantly trying to adjust a single PCB.

3. Improves Product Quality

The PCB panelization process creates a better product since it's easier to create smaller circuits that are less likely to have any issues.

Panelizing also means you can increase the number of PCBs per board which is important for production time, cost, and work efficiency.

This method can be used in many different types of manufacturing sectors which makes it adaptable and versatile. Pcb panelizing allows you to design with versatility so your circuit boards will fit more easily into certain applications like aerospace systems or medical devices.

4. Prototype PCB Panel help add unique designs

Designers can often take advantage of PCB panelization to add unique designs into their prototypes which are less costly and more efficient.

The PCB panelizing process also allows for cheaper PCBs since you're making smaller boards, so this might be a good way to go if your goal is to make products that will sell at lower prices.

Panelizing makes it easier to create custom-sized PCB layouts since the design doesn't have any constraints due to size or shape; one large board could never do what small panels can achieve.

This means that PCB panelized designs offer many potential benefits and advantages in production time, cost-efficiency, and ease of use for designers who need versatility in their circuits with each PCB panelized PCB layout.

5. Protects PCB from shock and vibration

PCBs are very sensitive to shock and vibration, which PCB panelizing helps protect against. Panels help keep the boards from coming into contact with each other, which can reduce problems like PCB warping or PCB delamination due to humidity exposure, both of which will compromise a circuit board's usability.

There is also less risk of panels sliding inside their frame because they're more tightly packed together; this could cause damage during shipping if it were happening on one large PCB panelized PCB layout instead of small PCB panels being done separately in smaller batches.

6. PCB Panelization boosts the Output

One of PCB panelization's biggest benefits is the boost in output, which can be done by increasing production time or adding more PCB panels to each board.

The PCB panelizing process also helps improve product quality because it has less risk of processing errors due to not having long periods where your work isn't getting completed, or products aren't being shipped out. This means that you're less likely to have issues like PCB warping or PCB delamination due to humidity exposure, both of which will compromise a circuit board's usability.

Making smaller boards instead of one large piece allows for quicker shipment times and better use of materials since there are no unnecessary waste-products produced during manufacturing and faster PCB production rates.

Types of PCB Panelization Explained

PCBs are routed or panelized using different methods: V-groove Panelization, Tab Route Panelization, or Perforated Tabs. These route or panelized types are not developed equally.

Type 1: V-groove Panelization

The V-groove method is the most popular way of panelization; it has been around for decades. When applied to PCB panelization, it involves cutting the circuit board half lengthwise and inserting a groove into each side. The grooves are then populated with aligned PCB components, so the circuits line up on both sides.

Type 2: Tab Route Panelization

This is a newer type of panelization which uses tabs inserted into the PCB circuit at regular intervals instead of grooves. The process involves cutting routes into two separate sheets and then inserting tabs into them until they meet. This method results in a more consistent design sheet layout, so each board has a uniform appearance.

Type 3: Perforated Tabs

Perforated tab PCB panelization is a newer form of making circuit boards that involves laying out patterns on the surface of printing boards with perforations that match up with predrilled holes in a different panel. This type of PCB panelization allows for the insertion of components into the top and bottom conductive layers.

Important factors to consider when Panelizing PCBs

The PCB board must have enough function and strength, and designers should ponder the following aspects;

1. Gap between panels

The recommended gap of 0.05 inches between V-grooves and components is essential for appropriate mechanical attachment of components. If the components are taller, the gap should be increased. If there are broad connection areas, the gap should be reduced to 0.02 inches or less.

2. Label Placement Problem

Component numbers in the middle groove must not overlap unless a label is attached with a heat-resistant adhesive. Also, avoid mounting components directly over exposed copper traces or vias; you may have to use smaller capacitors and resistors instead of larger ones to ensure there is space for your hands during assembly.

3. Proper Handling of Components

The components must be oriented and positioned so that their numbers are easy to read after assembly. Also, ensure enough space around the leads of surface-mounted components for soldering and component removal without damaging the circuits or nearby connections.

4. The Location of the Perforation

Perforations are created by a special press. The perforation must have sufficient strength for mechanical attachment of components and be easy to pry apart with one hand. However, it must not cause structural damage that will affect circuit performance or the yield rate when perforating two panels together.

5. PCB Array Arrangement

For good assembly, make sure the components are placed on both sides of the board to be easily accessed by a machine. It is recommended to place components in lines or columns instead of circles or random areas since it is difficult for automated picking tools to grasp irregular shapes. Also, use different colors and materials and different fill patterns to make it easier for pick-and-place machines.

6. Other considerations

Quality Control

Because of the lack of a top layer, panels are not subject to visual inspection and only have to pass EMI/ radiation testing.

Safety Considerations

Panelization is the most popular method of mass production and is a way to avoid soldering by machine. However, hand assembly can cause overheating components during soldering, skin burning, and electrostatic discharge (ESD). To minimize these risks, engineers should reposition zero-value resistors near heat sinks or use surface-mounted capacitors instead of those with leads. When selecting components, consider the maximum temperature and proper ESD protection required for each circuit to ensure there is no risk of overheating in a mass production environment.

Design Guidelines for PCB Panelization

The following are some edge and processing array guidelines that help designers reduce errors;

1. Add Processing Edges:

Designers should add the standard processing edges to Vgrooves or the inner edge of 5mm-wide perforations. If they are not present in production, it may create problems during assembly. Also, make sure no copper traces remain exposed around the outer perimeter of panels.

2. Reduce Component Spacing:

To prevent components from being squeezed together, increase the spacing between adjacent components to 1.6mm. If there are many components or they have larger leads, increase the gap to 2mm and add a small row of lead-free solder masks between them. It is recommended to apply non-conductive paste or double-sided tape instead of solder for panelization. It will provide the same mechanical strength as soldering but can be easily removed by hand after inspection or repair if necessary.

3. Clearance:

Lead-free solder mask and the edge of perforations must be at least 1.6mm from components to avoid damage during assembly. To prevent debris from accumulating inside panels, add a clearance of 2mm between the leads of ground pins and those of adjacent inner layers.

4. Panel Thickness:

Panels with a thickness of 1.6mm are most commonly used for hand soldering, but adding another layer can reduce damage caused by ESD and prevent short circuits during automatic assembly. Also, the panels should be as thick as possible to avoid leaks between layers when screws or other fastening mechanisms are used.

Different Depaneling Techniques Explained

Before testing or the final assembly, the PCB arrays are depanelized as follows;

Hand Breaking:

Arrays are depanelized manually by breaking the board into two with a hand tool. This is used for small-panel production and individual testing, but high-volume applications require automation.

Punching:

There are two machines used for this method; a manual punch and a machine punch. Manual punches are more rugged and can be used with boards with many components, but they cannot handle high-speed production. Machine punches have pneumatic components and work well in automated environments.

Pizza Cutter/V-cut:

A pizza cutter is used to remove the panel from the array. It lifts copper traces but leaves them attached to the board and separated from other components. Also, it can be used with arrays of any size.

Saw:

Sawing is used to remove a panel from the array and cut some of the leads. It can be used on boards with very few components but creates dust as hazardous waste.

Router:

Routers have a spinning blade but are only suitable for producing smaller arrays. The main benefit of using this method is that it leaves no waste and can be used with components or circuit boards.

Laser:

A laser is not commonly used to depanelize PCBs because it requires high-speed processing, which means the panel cannot be removed without damaging the edges. However, it is often used for marking.

Conclusion

Panelization is the production of assembly line-ready PCBs. It requires precise design and layout. Once designers understand how it works, they can increase productivity by optimizing routings, improving electrical performance, reducing waste, and increasing panel strength.

Previous article:What You Need to Know about PCB Drill Sizes