General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

Solder Pad Repairing And Cleaning Up

Simon / 2021-04-25

Contents [hide]

When it comes to solder pad repair, there are two popular methods in use. The first one makes use of high-pressure curable adhesive and dry heat which sticks in the replacement pad. The other procedure uses two-part epoxy so that the replacement pad can be glued tightly to the laminate.

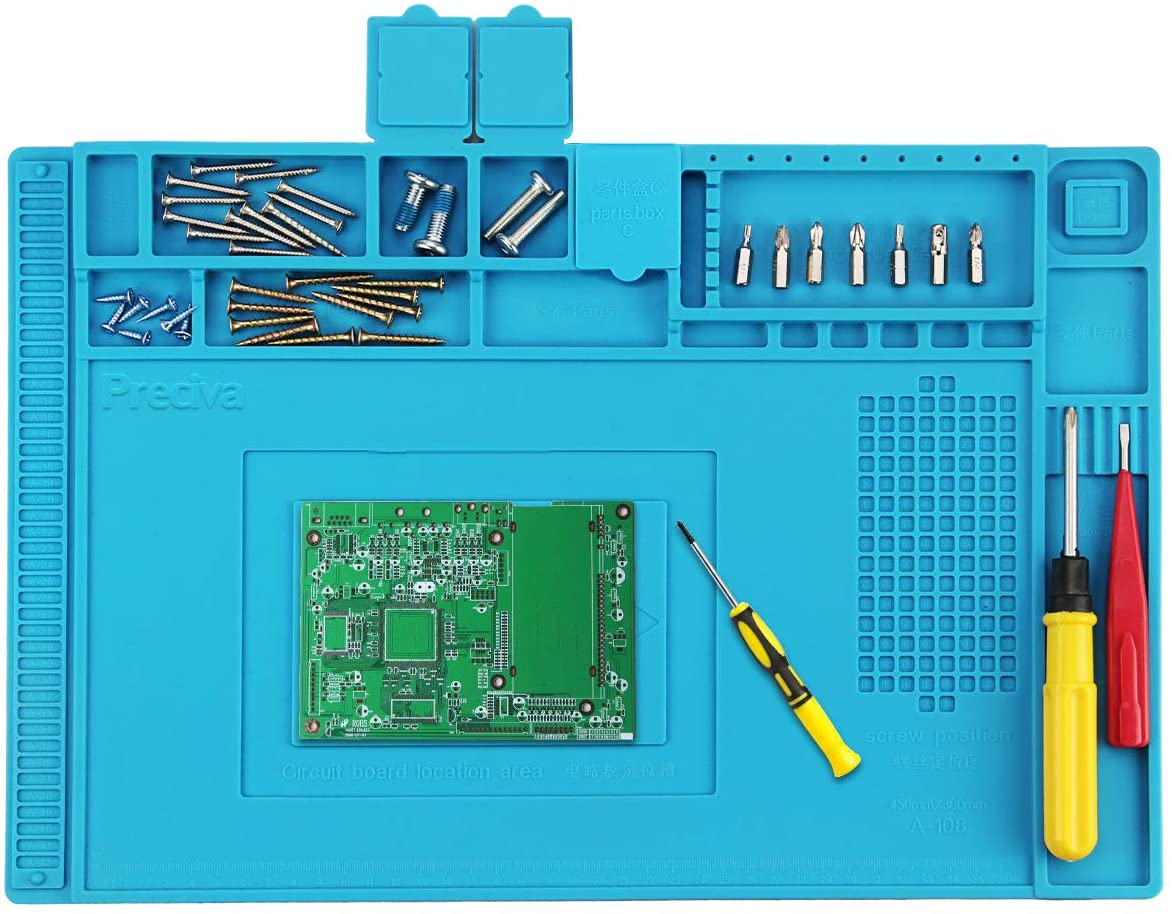

For a proper repair of the solder mat, you need to have the right tools to perform the work. Before going into the details of how to repair a solder pad and how to clean it up properly, let us know what a solder pad is.

What is a solder pad?

So, what is a solder pad? It is a designated surface you get to see on a board of an integrated circuit die. They are the small surface of copper in PCBs that allows soldering the specific component to the board. A solder pad is like a piece of copper where the component pins are soldered and supported mechanically.

You get to see two different types of solder pads, which are surface mount and thru-hole. The surface mount pads are for mounting devices on the surface. In short, soldering is done on the same surface where you have placed it.

Thru-hole solder pads, on the other hand, allow the pins of the part so that you can solder them from the opposite side from where you have inserted the part. These parts might be chips or transistors. In general, when the transistors or chips are removed or devices break down from the printed boards, it results in missing or damaged solder pads.

What are the important steps to repair missing solder pads?

Follow these steps to repair a missing solder pad so that your PCB gets ready for a new transistor or chip for further usage.

Clean the damaged pad: First of all, clean the damaged surface with isopropyl alcohol. Next, dry the surface with compressed air or lint-free clean cloth

Remove the pad: Use a sharp knife to cut away the damaged portion.

Clean the surface- Clean the surface in and around the solder pad. Also, remove burned or damaged laminate from the surface.

Clean up the solder mask: Use a toothpick to remove the solder mask if there is any.

Repeat cleaning of the surface: Use isopropyl alcohol to conduct another cleaning from the area. Use compressed air or lint-free clean cloth to dry the area.

Tin the conductor: Make sure to choose and use the right alloy to tin the surface where you have to attach the conductor.

Choosing the right circuit frame: After you tin the conductor, you have to proceed on to the next step. Take a sharp knife and cut out a conductor from the printed circuit board frame.

Tinning of the new conductor or pad: Using the right kind of solder alloy, tin the conductor or pad area. That way, it will overlap the main trace. Next, you have to make a mixture of hardener and epoxy resin. Makes sure to take them in small quantity. And, apply it to the surface on the printed circuit board. To cure it, you need to use open-air or use an oven. However, make sure to follow the guidelines given by your manufacturer.

Solder the trace or new pad to the conductor: Use tape that is specifically made for this purpose. Place the tape and hold the replacement pad. Next, make the lap joint by using appropriate solder alloy.

Clamping and curing: This involves the final step. Clamp the new trace or pad in the right place and cure. After curing, remove the clamp and clean it with isopropyl alcohol.

How to Cleanup Solder Pad?

There are many reliable and safe ways to clean up solder pads from the PCBs. Here are the best ways.

Grinding and scraping

You will notice that most of the time, the use of a scraper or knife in the hands of a trained technician is the most common technique used to remove solder pads from certain areas where you don't want them to be.

While no special environment is needed, fatigue is the biggest drawback if you are working on larger projects. Sometimes, mechanical erasers speed up the process. When you are removing a thin layer of solder pad, this is the most common, methodical, and controlled technique. Also, you can use it in collaboration with other cleanup techniques.

Milling and machining

So, will you use a milling machine to get rid of the solder pad? It might appear extreme, but it can be a precise and effective technique for removing the solder pad. Because sharp cutters will be in action, depth control is necessary. The milling system has to be fitted with a microscope to get clear visuals.

Carbide mills are the most common cutter. Because carbide cutters are sharp, they might penetrate the board surface. However, when you turn the cutter in the opposite direction, it produces effective results. To use this process, operator experience and skill are necessary.

Chemical stripping

Of all the techniques, this one is the most effective when it comes to removing solder pads from soldered surfaces or copper planes. Certain protective materials or masking tapes have to be placed on the PCBs in the surface to be stripped.

Next, apply the chemical stripper with a swab or brush. Because the chemical is liquid, it is hard to control. It attacks the coat and breaks it down. The most common chemical used is methlyene chloride. While they remove the solder pad quickly, they can deteriorate the material is exposed for a longer time.

Micro blasting

This technique is effective when you want to remove solder pads from many areas in a single circuit board. An abrasive metal is propelled through a hand-held pencil-shaped piece. This material blasts away the coating in no time.

This method produces static charges and friction during the process. So, extra care should be given when using static-sensitive PCBs.

Conclusion

Solder pad is an integral part of PCBs. However, when there is a need to repair or clean up, you can do that by following the necessary steps as discussed above with ease. So, the next time you encounter a missing or damaged solder pad, you know what to do.

Previous article:What is PCB Impedance Calculation and Why It Is Important