General, quoting & support.

Add: Building E, No.58, Nanchang Road, Xixiang , Baoan District Shenzhen City, Guangdong, China

Tel : 0755-27348887

Fax : 0755-27349876

E-mail : svc@pcbastore.com

What is LED Circuit Board?

Simon / 2021-01-24

Contents [hide]

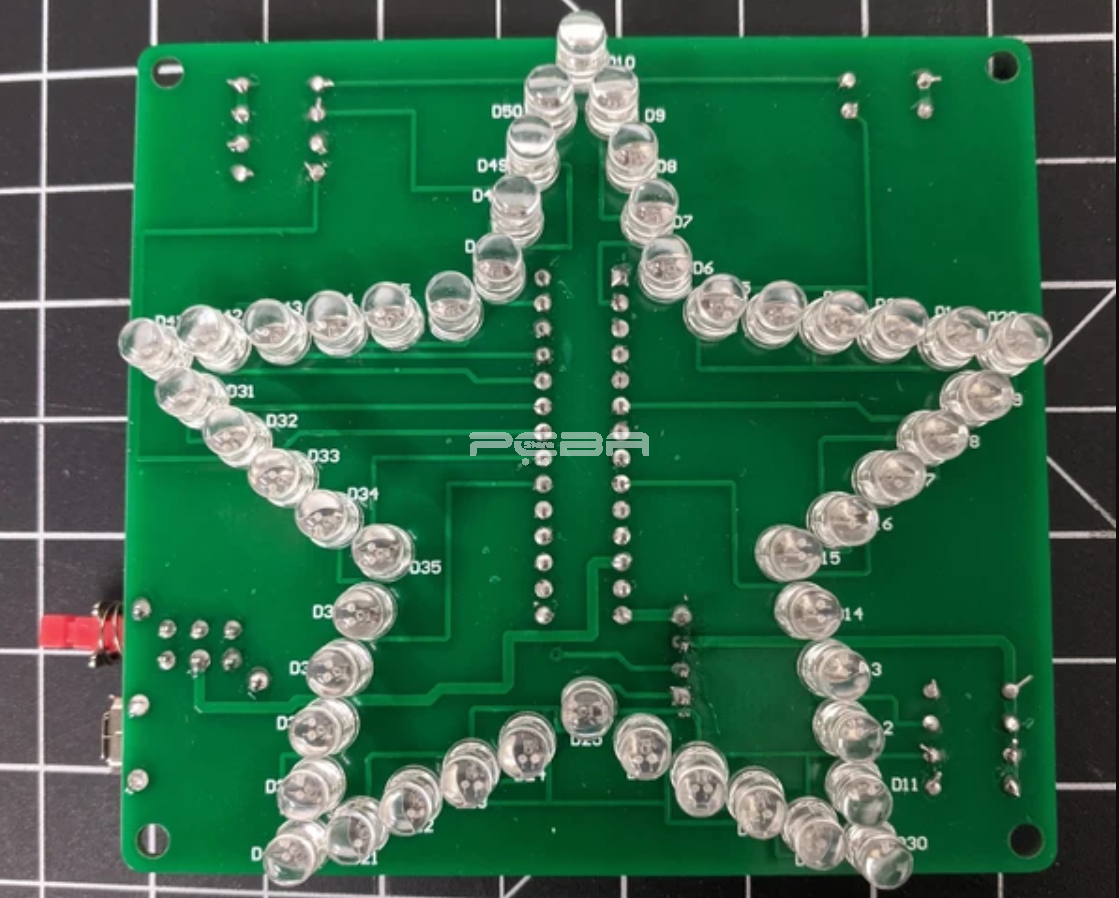

What is LED Circuit Board?

Let's begin by understanding what LED is. LED is a short form for light emitting diode. It is a well-known technology used for lighting in different industries. They change electricity to light with the use of a semiconductor. Unlike traditional bulbs, LEDs save energy up to 80%. Additionally, they are able to remain in good use for up to 25 times longer compared to the traditional bulbs. Of great importance still, they are environmentally friendly and their small size is still an added advantage.

Printed circuit board (PCBs) act as supports for LEDs. Essentially, they are thin boards made of various materials including: fiberglass and metals. The materials are used to connect electronic components electrically. LED applications use these boards so as to function effectively. They provide physical support to LEDs and switch heat from the bulbs to boost their performance and protect them from being damaged.

A LED circuit board has qualities that enable it to perform in the best way possible. It's important to point out that LED circuit board is the foundation of LED lighting. There are variations in LED circuit boards, and this makes them ideal for diverse applications. This means that the construction of a LED circuit board depends highly on its particular application. The construction of these circuit boards puts into consideration the setup, design, and the materials to be used. Some of the common materials used in the construction of LED circuit boards are: FR-4, Epoxies, and Metal-core.

FR-4 contains glass and epoxy. It is a common material. The disadvantage with it is that it is not efficient enough when it comes to the transfer of heat. Epoxies are a widely common option for the construction of LED circuit boards. The disadvantage with them is that they are less durable compared to other materials. However, they are known to be less costly as a manufacturing material. Lastly, PCBs manufactured using metal-core contain aluminum mixed with other metals and coated with copper. The best applications for these materials are the ones that involve heat transfer. They are good in offering high quality thermal conductivity as well as electrical insulation.

As a result of the major function of heat transfer in LED circuit board applications, metals, and particularly aluminum are the most commonly used materials.

The Advantages of LED PCB

There are notable advantages that LED PCB offers. They include:

Quality performance: Manufacturers and designers prefer making use of LED PCB because of their capacity to produce high performance. Customers opt for products that have quality performance because their needs will be met accordingly. Therefore, LED PCBs remain popular because they're able to offer exactly that.

Flexibility of designs: For those who prefer products that offer design flexibility, LED PCBs are a better option. It's possible for customers to have their appliances designed according to their designs of choice. Moreover, you're able to gain access to different designs of LED PCBs in the market.

Energy efficiency: In a day and age where energy consumption can be costly, it's valuable to use appliances that save energy as much as possible. The use of LED circuit boards goes a long way to help users save a high amount of energy.

Cost effectiveness: Cost effectiveness is a pivotal characteristic of LED circuit boards. Any appliance that saves costs for both manufacturers and customers is a great option. If you would want to save money on electrical applications, consider using LED circuit boards.

Ease of use: You don't need training for you to use the appliance. It is easy to use, thus it's a preferred choice for many users. In addition, in case of any problem developing with a LED circuit board, it is easy to diagnose it and also make repairs to it without necessary contacting a technician to fix it.

Less noise: Most electrica appliances produce noises that can be annoying but LED circuit boards are different. Despite producing effective lighting, they don't make a lot of noise as other applications do.

It is compact: The quality of being compact gives a LED PCB a great advantage. It is because of this factor that manufacturers are able to position it well into various areas like cars and others.

Stable Placement: The LED circuit board components resist movements since they stick well to the board. It is because of this characteristic that manufacturers are able to use it effectively in appliances that move like the headlights of a car. Drivers don't have to worry about components being displaced and the development of electrical short circuits as the car makes movements.

Availability is different sizes, intensities, and colors: This advantage gives users the freedom to choose what suits their needs the best.

Lightweight: For the users who like using appliances that are lightweight, LED PCBs are a viable option for them.

The Applications of LED PCB

There are various applications of LED PCB including:

Telecommunications: The reason why the telecommunications industry used LED PCBs is because of their capacity to remain durable and transfer heat. Most of the appliances in the industry produce a huge amount of heat, so these circuit boards come in handy.

Transportation: LED PCBs are widely used in transportation and traffic. You are often used in spotlights and headlights. In cars, they are used in applications like headlights, indicators, and brake lights. Also, LED PCBs are commonly used in street lighting, traffic lighting, highway tunnel lighting, and signal lighting. They are also used in the aviation industry for applications like indicator lighting and interior lighting.

Consumer electronics: Consumer electronics manufacturing is making massive use of LED PCBs. Some of the products that make use of them include: televisions, computers, and smartphones. It's important to take note that consumer electronics are highly heat-sensitive and, for that reason, LED PCBs made of aluminum are ideal because of their capacity to transfer heat.

Medical: In the medical industry, equipment like lighting tools for surgery as well as hospital lighting uses LED PCB.

Consumer lighting: This includes the likes of lanterns, spotlights, flashlights, and lanterns.

How to Wire Multiple LEDs on a Circuit Board

If you want to wire multiple LEDs on a circuit board, you do so through parallel wiring. When you are wiring LEDs in parallel, you're simply creating different mini circuits with each having their own power supply. Every circuit contains of the battery, a LED and a resistor.

How to Solder LEDs to a Circuit Board

Here are the steps to follow on how to solder LEDs to a circuit board as below:

Tinning the tip: For you to solder, you have to use a tinned tip. In order for you to properly tin the tip of an iron, you have to apply solder to the tip and then make sure that you coat it thick. Afterwards, you should wipe the extra solder with a wet material and then reapply a small quantity of solder to the tip once again.

Ensure that the solder surface is clean: The surface has to be clean for it to have quality results. Thus, ensure that you take away any dust, dirt, or any element that's on the surface. Learn more details about how to clean the pcb here.

Tin the surfaces: Before the final connection is done, the wires should be tinned. Apply a thin layer of solder on the wires. Ensure that the solder sticks to the wire. Next ensure that the solder pad is tinned too. Apply solder to the pad. The solder has to flow evenly on the entire pad. Afterwards, take the iron away and allow the solder to firm up.

The Final connection: Use a tinned tip and surface to hold the two pieces being soldered with the iron. The solder on each surface has to flow. Remove the iron quickly and after the solder hardens, both components should be soldered.

It's imperative to take note that soldering can be difficult, especially if you've never done it before. It is possible for you to damage a component. The important thing to remember is that irons are hot and LEDs don't like exposure to a lot of heat. So, you have to be extremely cautious with the temperature setting on your iron and the amount of time you use to apply the iron on the surface. It should take a few seconds for solder to flow and attach itself on a surface.

Conclusion

LED circuit boards are an indication of how much electronic technology has grown over the years. The wide scopes of electrical applications that use LED PCBs are a testament of how popular they are in the electric world. Certainly, the popularity of LED PCBs is not without many benefits associated with it. It is these advantages that make manufacturers and users opt for them instead of others. In the same vein, these circuit boards are applicable in diverse industries. The fact that they are applicable in different industries shows that they have diversity of setups, designs, and materials for construction. It is undoubtedly that LED circuit boards will continue to drive the functioning of electronic applications for a long time. If you have requirements for LED PCB, please feel free to contact us for a quotation.